Rollforming machines have become an essential part of metal forming and production processes, especially in high-volume and repetitive manufacturing. These machines transform flat metal sheets or strips into desired profiles through a series of rollers. Rollforming technology allows for the precise and continuous production of metal profiles, making it a preferred method in industries such as construction, automotive, aerospace, furniture, and energy.

Recent Innovations in Rollforming Technology:

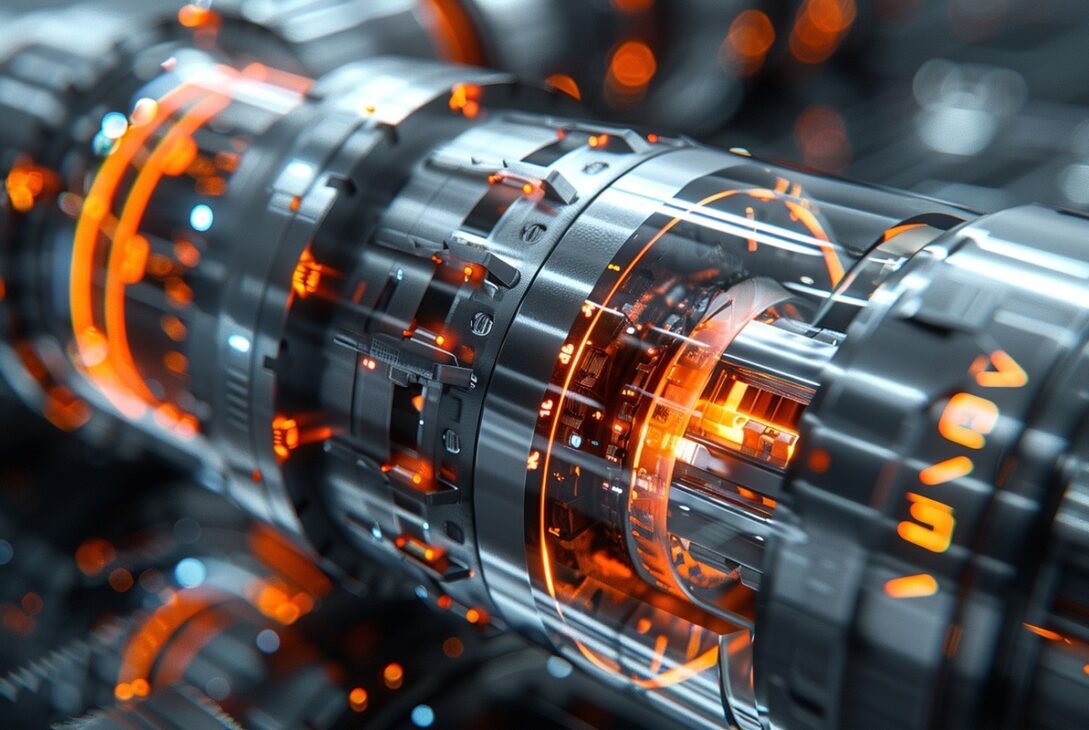

Rollforming machines have seen significant advancements in recent years, largely driven by digitalization and automation through Industry 4.0. These innovations are focused on increasing production speed, improving efficiency, and minimizing errors.

- The Growing Role of Automation:

Automation plays an increasingly important role in modern rollforming machines. Advanced automation systems can manage most of the production process without the need for human intervention. Real-time data monitoring systems and sensors track each stage of production, detecting errors early and making immediate adjustments. This reduces downtime and significantly minimizes defective products. Additionally, automation helps reduce labor costs by requiring fewer operators to oversee the production process. - 3D Rollforming Technology:

While traditional rollforming machines primarily form metals in two dimensions, 3D rollforming technology allows for the creation of complex three-dimensional profiles. This innovation is particularly impactful in industries such as automotive and aerospace, where lighter and more durable profiles are essential. For example, automotive chassis components can be produced using 3D rollforming with less material, resulting in lighter, more fuel-efficient vehicles. - Real-Time Data Analytics:

Rollforming machines are now equipped with smart sensors and digital monitoring systems that provide real-time data to operators, allowing for more precise control of the production process. This technology enables manufacturers to identify potential issues early and make adjustments on the fly, reducing downtime and improving overall production efficiency. Additionally, real-time data can be used for long-term planning and process optimization. - Modular Rollforming Machines:

Recent years have seen the rise of modular rollforming machines, which offer greater flexibility. These machines can be easily adapted to different projects and production needs, providing manufacturers with cost savings and versatility. For instance, a rollforming machine used in the construction industry can be modified to produce automotive components with minimal adjustments, saving time and reducing the need for additional machinery. - Energy Efficiency and Sustainability:

Energy consumption and environmental sustainability are becoming increasingly important in industrial processes. New-generation rollforming machines are designed with energy efficiency in mind, featuring energy-saving motors and precision cutting systems that minimize material waste. This not only lowers operational costs but also reduces the environmental impact of large-scale production.

Future Trends:

The future of rollforming technology promises even more innovation and efficiency. Key trends expected to shape the industry include:

- Fully Automated Production Lines:

With the integration of artificial intelligence and machine learning, rollforming machines will evolve into fully automated production lines. These machines will be able to self-optimize, making real-time adjustments to improve production efficiency and reduce errors, further lowering operational costs while enhancing product quality. - High-Strength Material Processing:

Future rollforming machines will focus on processing lighter yet stronger materials. Lightweight metals and composite materials will lead to more efficient and eco-friendly production processes. This trend will be particularly important in the automotive and aerospace industries, where lightweight products result in greater fuel efficiency and cost savings. - Full Integration with Industry 4.0:

Digitalization and Industry 4.0 are pushing production lines toward fully interconnected and smart systems. Rollforming machines will seamlessly communicate with other machines in the factory, contributing to a smart manufacturing environment. This will lead to more efficient management of production processes, reduced downtime, and enhanced product quality.

Conclusion:

Rollforming machines have transformed metal forming, and their role in modern manufacturing will only continue to grow. With continuous production capabilities, automation features, and energy efficiency, these machines are valuable in both large-scale and small-scale production environments. Innovations such as 3D rollforming, real-time data analytics, and modular designs will ensure that rollforming machines remain a key component of future manufacturing processes, driving greater flexibility, efficiency, and sustainability.

Automation Rollforming Technology

Last modified: 17 September 2024